The Art of Coverslipping

In the world of histology, can coverslipping be considered a type of scientific art?

The answer: Yes!

Coverslipping is completed with the assistance of a finely tuned machine and is the final step in a chain of steps that take place when preparing a tissue specimen for examination under the microscope.

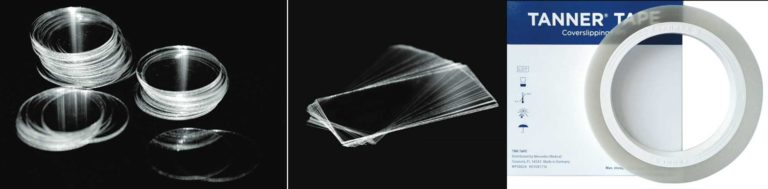

Histological samples need to be mounted under a coverslip for examination. The art comes into play in the way the specimen is mounted: there are various mounting techniques and many ways coverslipping can go awry. The true histological artist knows which is the best coverslipping technique to use and follows the precise procedure for the chosen technique.

There are many ways a sample can be accidentally ruined during mounting (and after all the steps already taken to get to the mounting stage!). But when the art of coverslipping is present, so are the lack of mistakes in the mounting-under-coverslip process. Furthermore, knowledge of refractive index (RI) is essential. Therefore, it’s a definitive “yes” to say that the coverslipping process takes experience — and a certain scientifically artistic finesse!

Coverslipping: A Skillful and Important Laboratory Art

Using their expertise and aptitude, artful histologists place one end of the coverslip onto a mounting slide and continue so that the mounting is placed in the very center of the coverslip. This is achieved by utilizing a special dissecting needle that helps the technician carefully and slowly lower the coverslip into the perfect position.

The adept histologist knows how to use the right amount of mounting fluid (the “media”) to fill the coverslip without having any excess media ruin the coverslipping process.

If there is too little mounting media used, air bubbles can form on the coverslip’s edges, negating the tight seal needed in coverslipping a tissue sample.

If there is an excess of mounting media used, the coverslipping process will be sloppy, allowing the tissue samples to move and slide around beneath the mounting slide.

The Lab Artist’s Coverslipping Steps

The adroit histologist has completed the fixing, embedding, sectioning, staining, dehydrating, and clearing steps all needed for the ultimate tissue examination step: mounting the specimen beneath the coverslip. This last step is called coverslipping. Coverslipping begins with another series of skillful mounting media musts as this is how the skilled histologist protects the tissue specimen by bonding the specimen, the slide, and the coverslip together.

- The refractive index has to mesh, as closely as possible, to the mounting media being used

- Transparency and lack of color is vital for the proper end result

- There must be a non-stick (consistency) to the mount and the tissue sample should harden rapidly. The tissue should never shrink away from the mounting media’s edge

- The expert histologist ensures nothing contaminates the sample to be coverslipped; this requires speedy but accurate work – and, of course, no hair brushing or sneezing or coughing anywhere near the sample!

- Dehydration of the sample (also known as “clearing”) is done using the correct type of clearing agent

- During the procedure, the sample should never crystalize or crack even the slightest bit

When the mounting is sturdy and stable, the laboratory artist has completed the coverslipping process and is ready to study the sample under the microscope.

Ensuring Specimen Quality with A Lab Investment that Saves Time, Saves Labor, and Saves Coverslipping Artistry

Taking on the cost of an automated coverslipper today will ensure increased laboratory productivity and performance tomorrow. And for many tomorrows to come!

The investment in a high-quality coverslipper not only saves time and money for your lab, the investment also preserves the art of on-target coverslipping through higher quality and faster drying slide capabilities; increased productivity due to larger slide unloading stations; optimal labor efficiency; a reduction in calls for costly equipment servicing; and more improved safety for lab workers due to excellent venting capabilities.